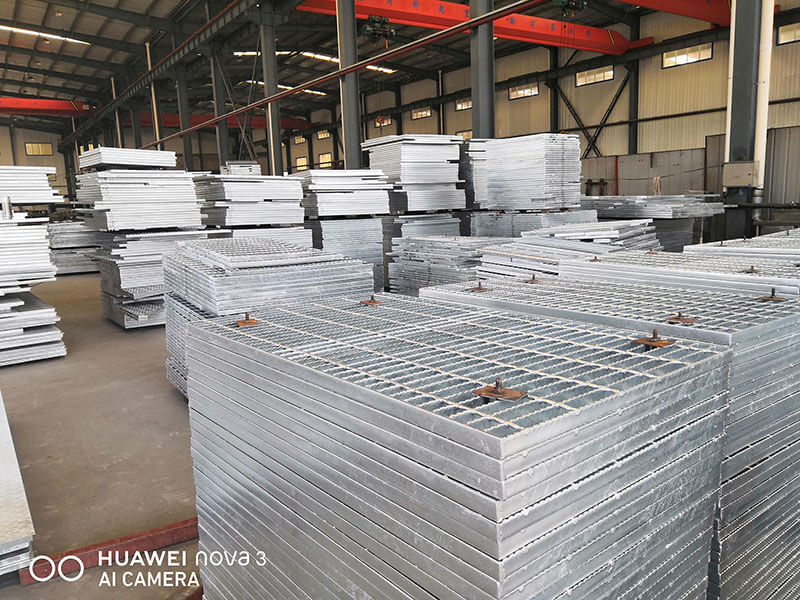

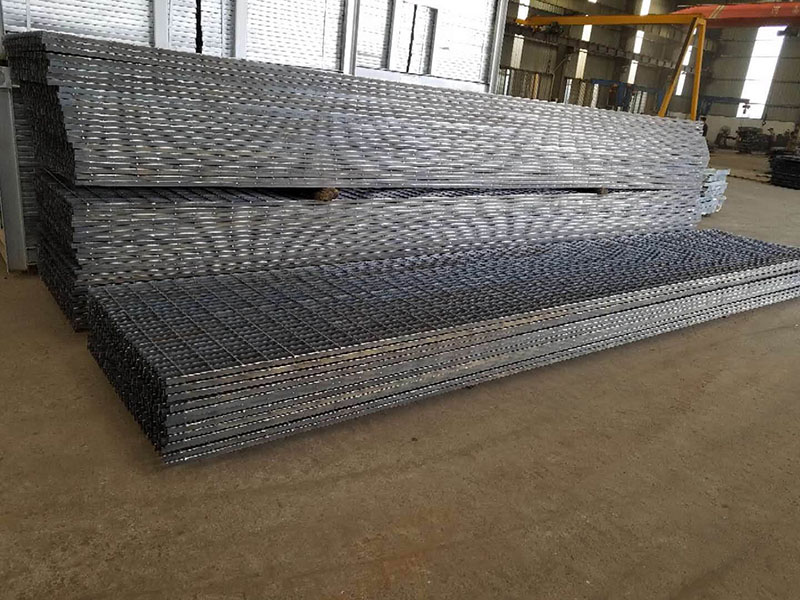

Ston is one of professional manufacturer of gratings, such as: galvanized steel grating, hot dip galvanized steel grating, stainless steel grating, aluminum grating, untreated steel grating, steel grating panels, untreated drainage grates, hot dip galvanized drainage grates, steel drainage grates for shipbuilding, trench grating and grating clips and most of grating is regularly exported to USA, AUS, Kuwait, Chile, Singapre, Indonesia, Africa, UK and so on. Our grating always have a good reputation in the world.

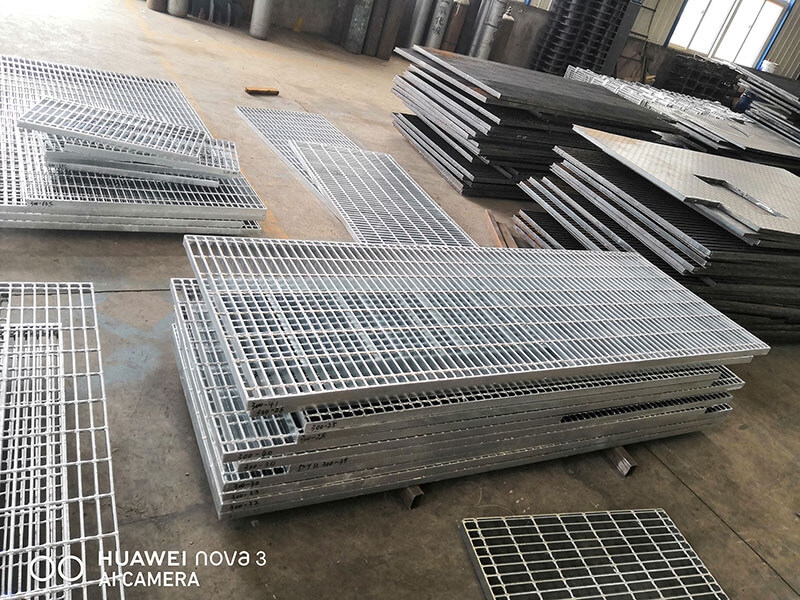

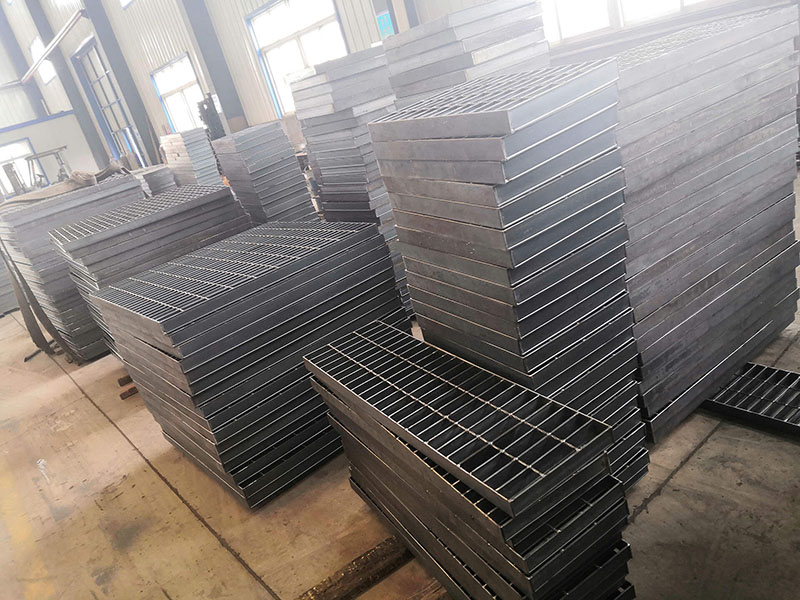

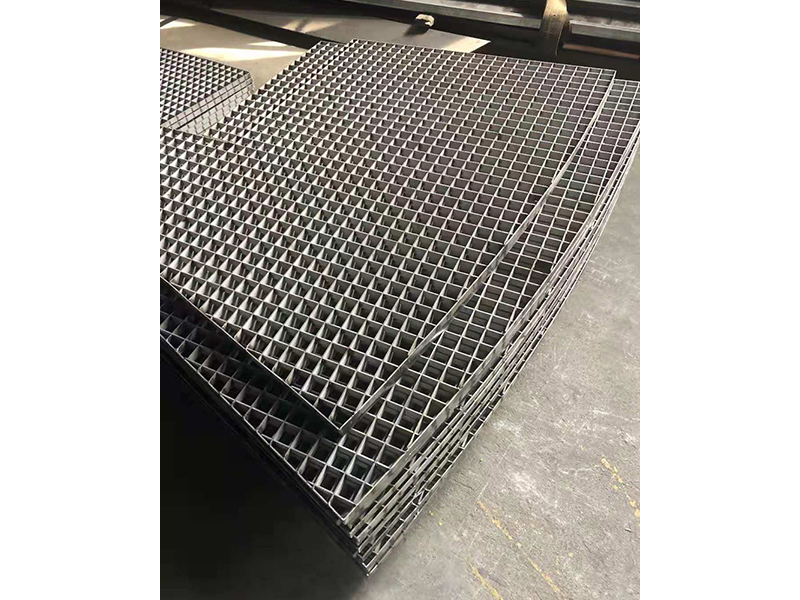

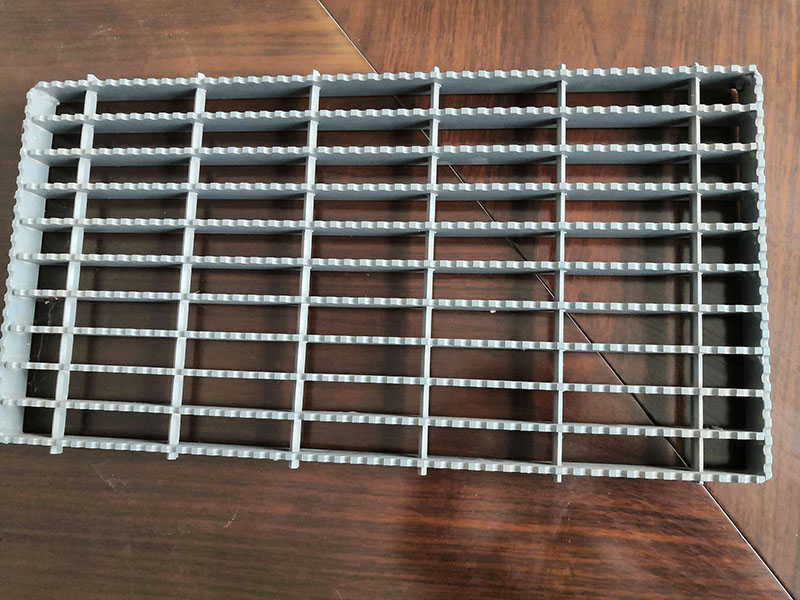

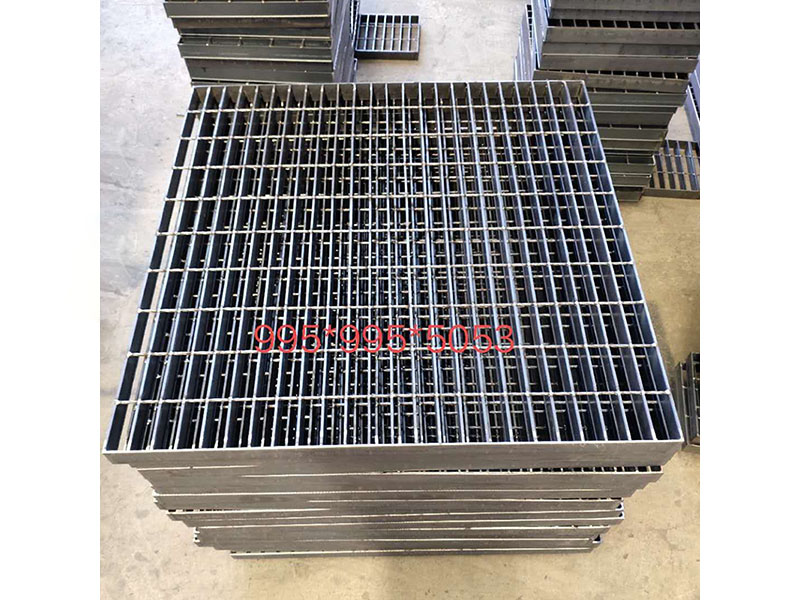

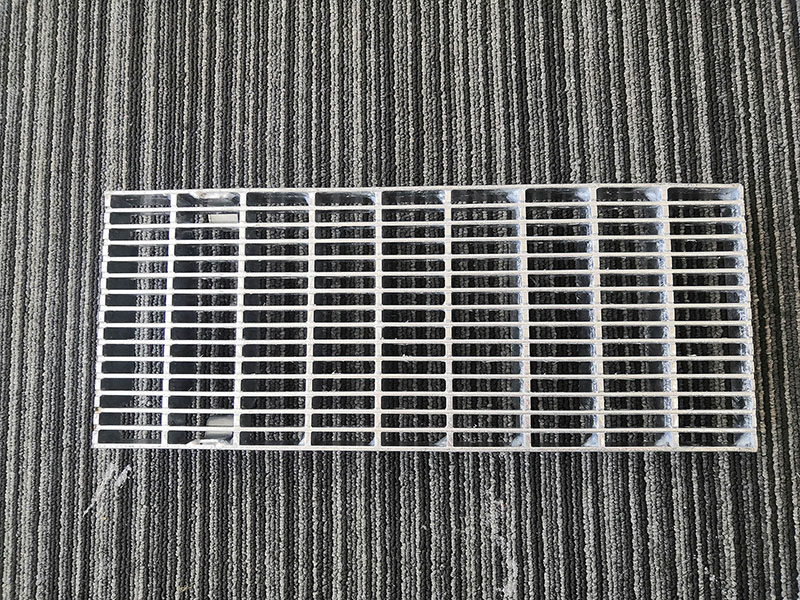

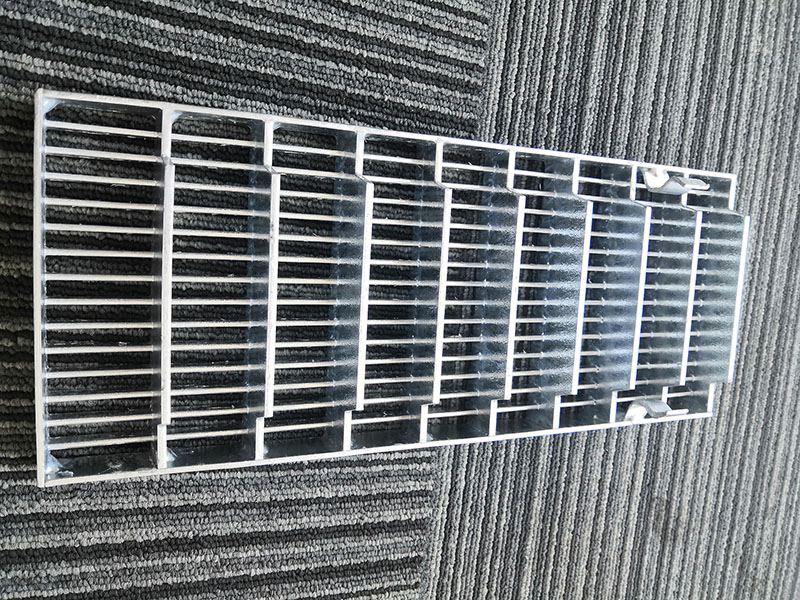

The steel grating is a kind of steelwork made by crosswise welded bearing bar with a certain space and cross bar (twisted square steel bar, square steel bar, round steel bar, bearing bar, etc.) which shows square grid in the middle.

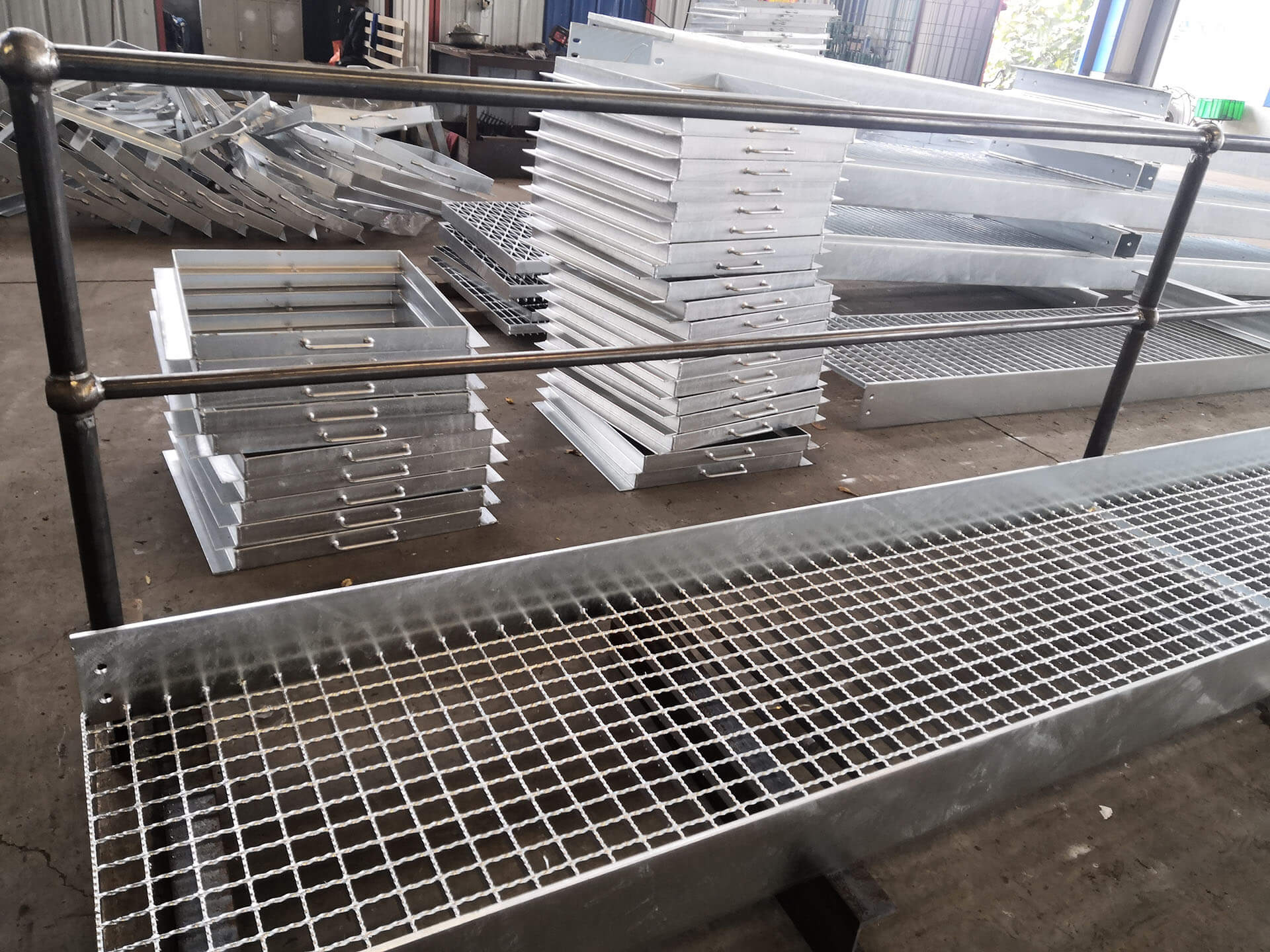

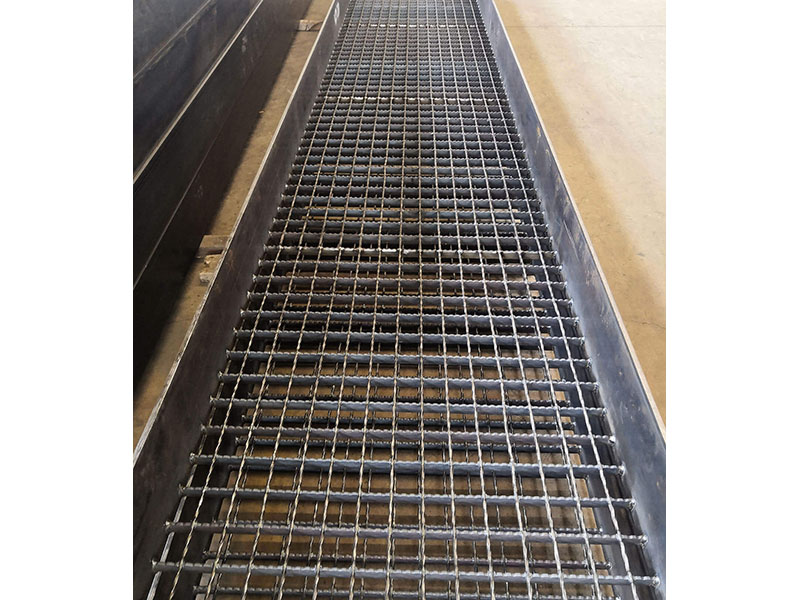

The steel grating mainly used to produce trench covers, structural platforms, stair treads, etc.

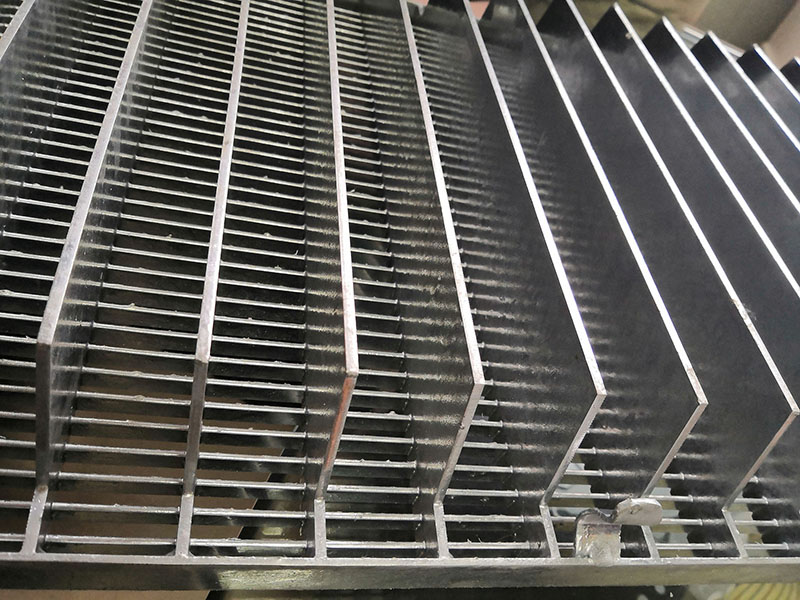

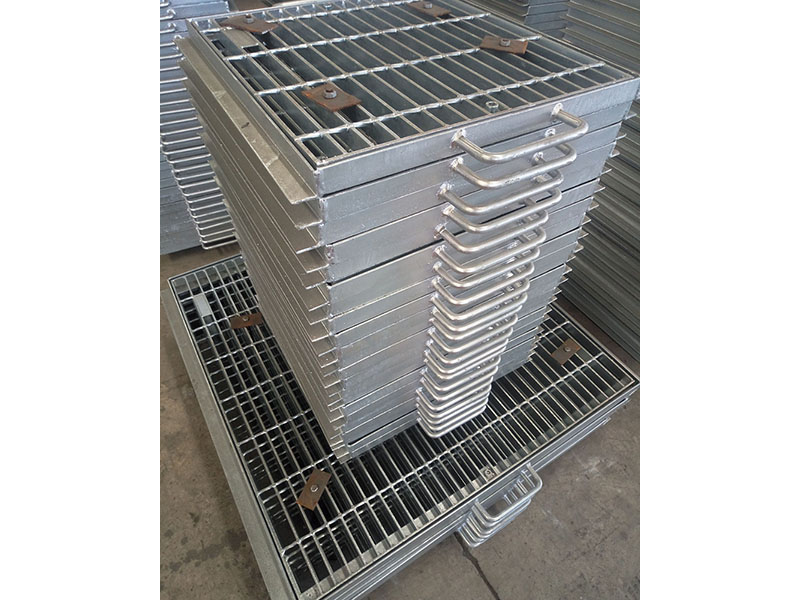

Hot dip galvanized steel grating has three kinds of steel gratings, they are plain style steel grating, serrated style steel grating and I bar type steel grating. They are widely used in steel structure platforms, stair treads, sidewalks, drainages and well covers etc.

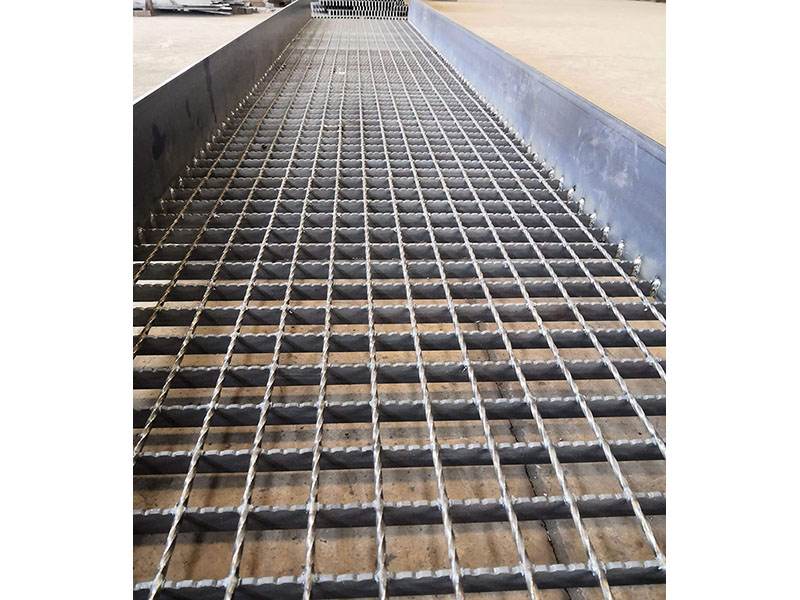

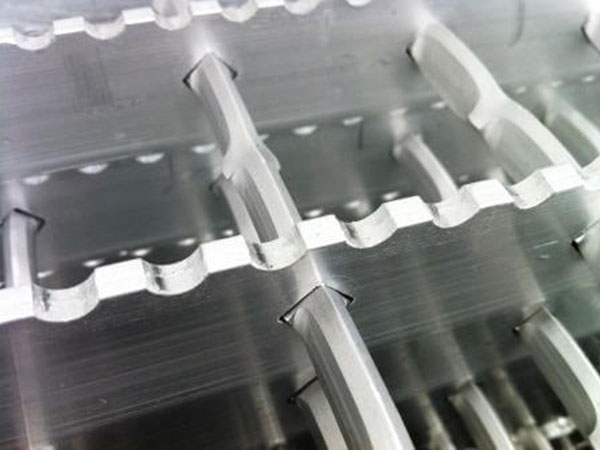

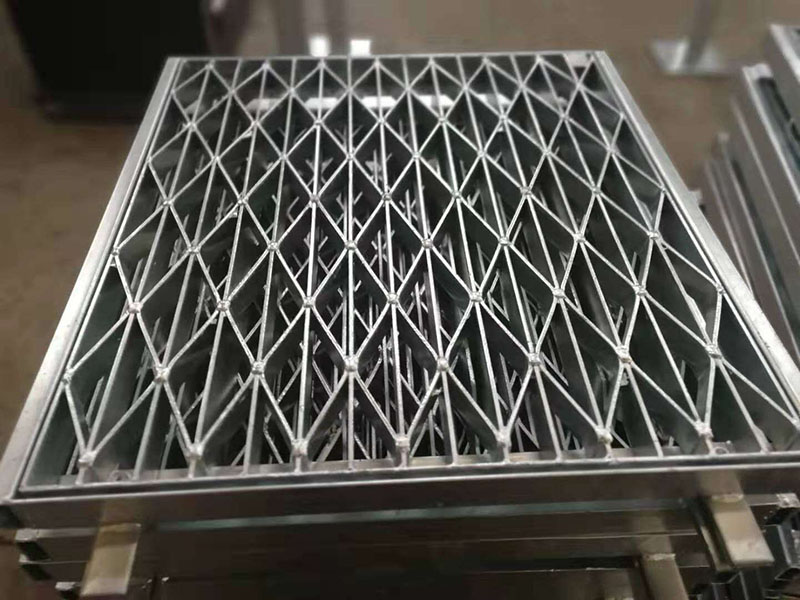

The cross bar usually use the twisted square steel bar. The material of steel grating is commonly carbon steel and the surface is usually hot dip galvanized to prevent oxidization. Besides, the steel grating also can be made by stainless steel.

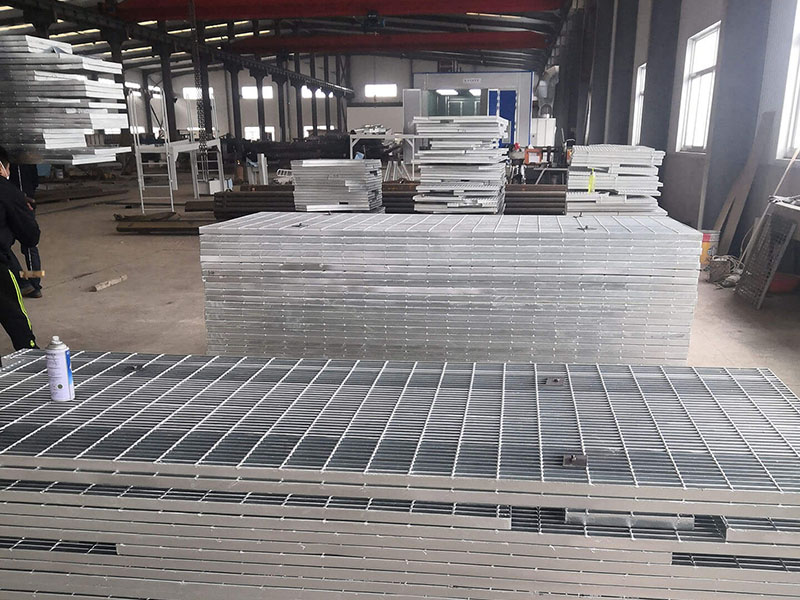

The properties of steel grating are ventilation, light-catching, heat dissipation, anti-skidding and anti-explosion etc.

We can design and manufacture standard steel grating and in custom shapes per client's requirements.

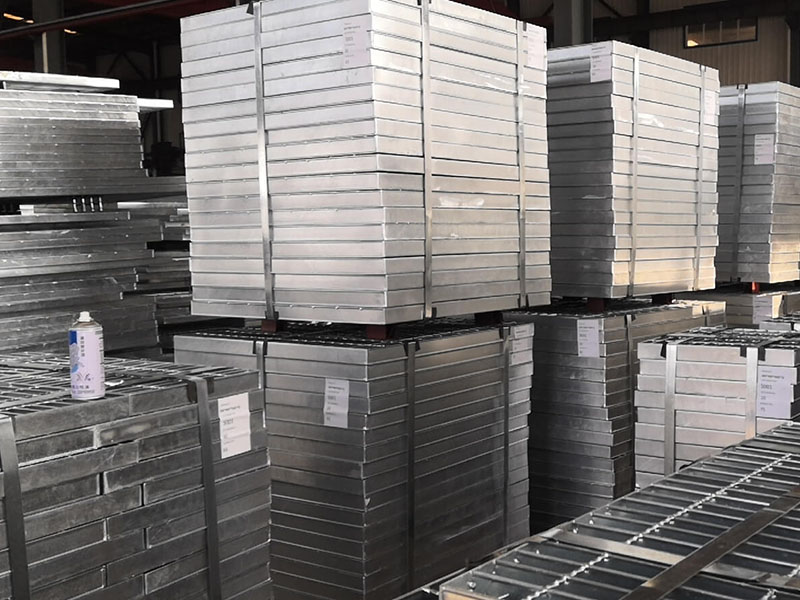

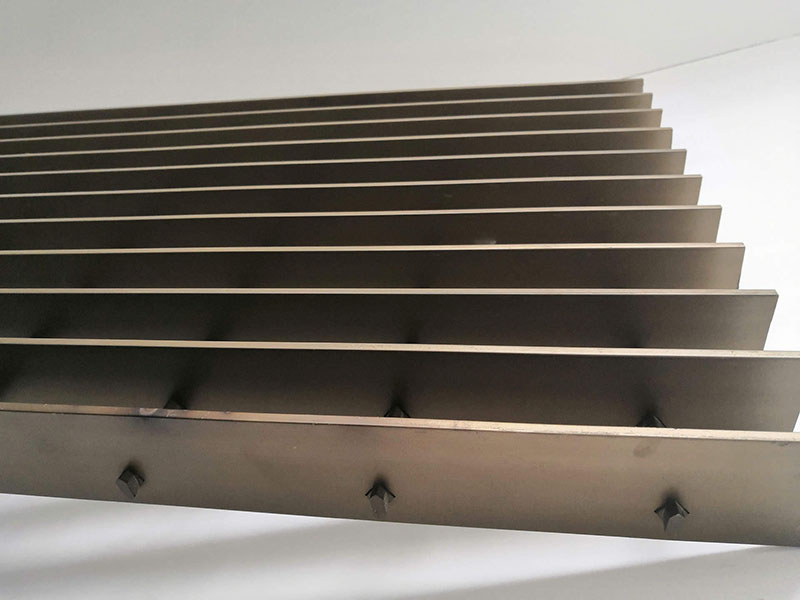

Galvanized grating, also called galvanized steel grating or galvanized steel bar grating, refers to the steel bar grating made of mild carbon steel through hot dipped galvanized surface treatment.

Mild carbon steel provides an economical, high strength for uses in most industrial and commercial applications. And hot dipped galvanized surface treatment supplies excellent corrosion resistance performance for durability.

Steel grating is available in various material, such as stainless steel, aluminum, and galvanized steel. Among them, the galvanized steel grating is the most cost effective and economical type with long service life and high load. And it is the most widely used in both industrial, commercial and residential applications.

Hot-dip galvanizing is the most effective, economical and durable process to protect steel from atmospheric corrosion. The process is based on immersing the steel in a 450º molten zinc bath. The zinc covers the steel and protects it from atmospheric oxidation processes.

Advantages of Galvanized

1, It is an economical treatment that guarantees total interior and exterior protection against corrosion, due to the complete immersion of the parts in the zinc bath.

A total protection in case of blows or alterations of the material, due to the "pile effect" between Zinc and Iron.

2, A "0" maintenance with the great economic savings that it supposes.

Long-lasting, guaranteeing protection against corrosion for long periods due to the following characteristics: Very low corrosion rate of zinc; Great thickness of the zinc layer applied in the process.

China Grating Manufacturer, also offer stainless steel grating.

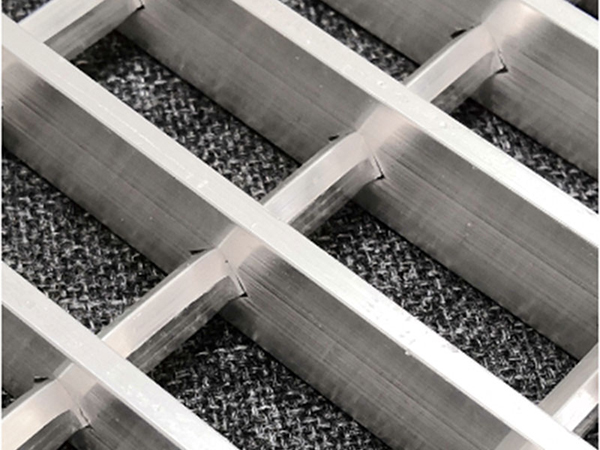

Stainless steel grating is regarded as industrial grade bar grating, which is extremely strong, durable and corrosive resistant for all load bearing applications and is primarily used for pedestrian and light vehicle traffic.

Applications of stainless steel grating

Stainless steel grating can provide durable grating solution for corrosive resistance and minimum carbide precipitation are important considerations, typical applications include stairs and platforms for chemical production and storage, food processing and water and waste water treatment plant.

China Aluminium Grating Manufacturer--Yantai Ston Metal

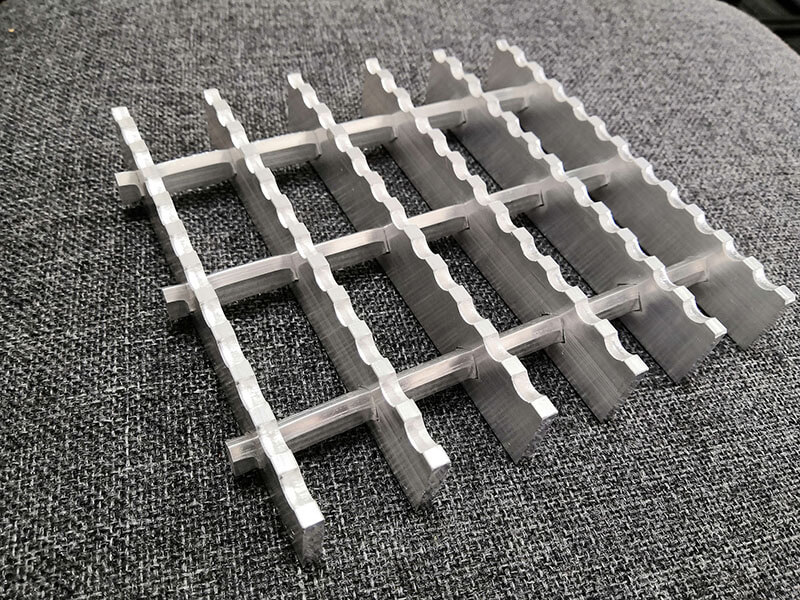

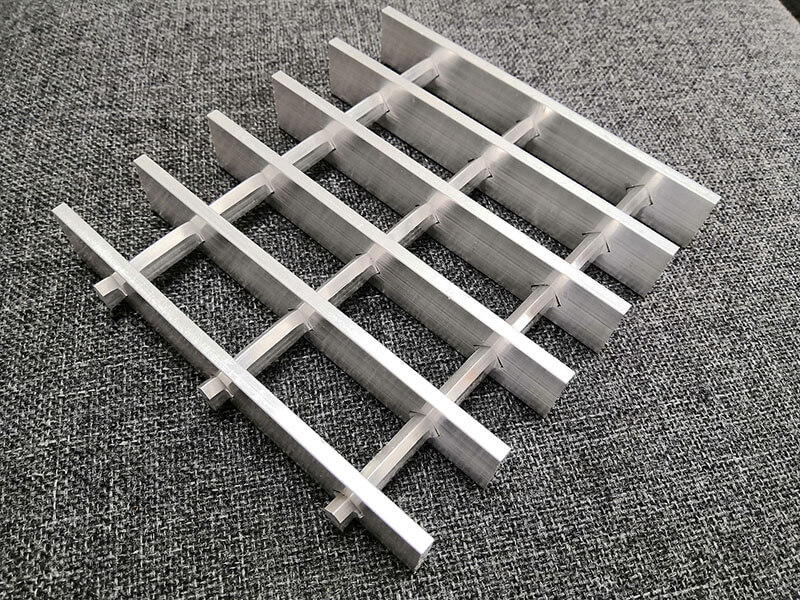

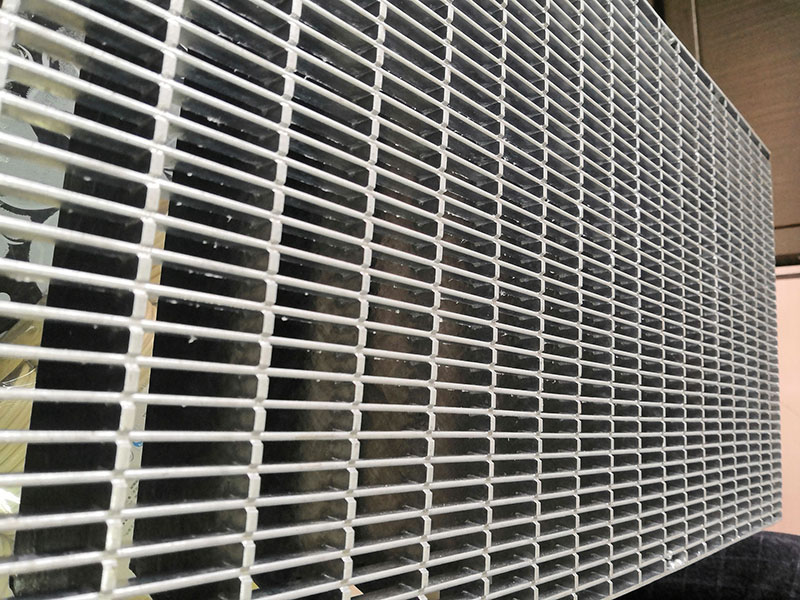

Aluminum grating is an ideal choice when corrosion-resistant, lightweight materials that do not affect its load capacity and mechanical strength is required. Made of ASTM B221, 6063 or 6061 alloy, aluminum grating has great versatile and durable and is mainly used for platform ceilings and outdoor curtain walls.

Features of Aluminium Grating

Light weight, high strength, no solder joints, strong corrosion resistance, energy saving, low maintenance cost, strong connection and other advantages.

Applications of Aluminium Grating

Because of its light weight, corrosion resistance, and non-sparking, Aluminum gratings are widely used in indoor ceilings, outdoor curtain walls and other decorative applications due to its lightweight, excellent corrosion resistance and non-sparking properties. It is suitable for industrial applications where the strength-to-weight ratio is important, such as wastewater treatment plants. It is mainly used for safety protection and served as walkways, floors, platforms, stair treads, fences, etc.

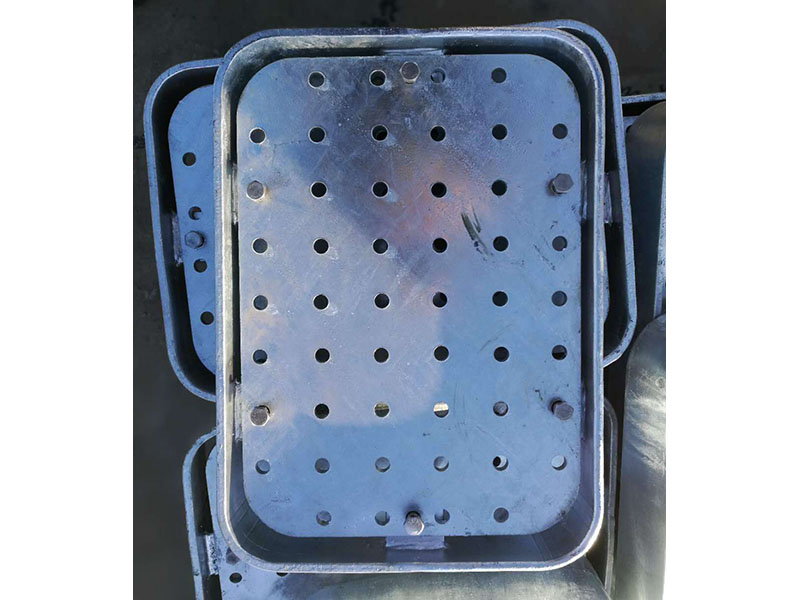

Untreated Drainage Grates

Hot Dip Galvanized Drainage Grates

Steel Drainage Grates for Shipbuilding

Drainage covers are commonly referred to as drainage steel grating, rainwater grate, and drainage grate. They are usually divided into two types. One is flat steel and twisted square steel that are arranged crosswise and welded. That is, ordinary pressure-welded steel grating; the other is formed by cross-welding flat steel and flat steel, that is, inserting steel grating.

· Galvanized Steel Grating Service Life

1. The reasons which can affect the steel grating service life:

1). The steel grating service life is depended on the environment condition and whether the zinc layer is destroyed or not.

2). Another reason is the industries applying, if the steel gratings are used in the chemical industry, the service life will be shorten due to the strong corrosivenes.

3). The steel grating service life will be different according to it is used in indoor or outdoor.

2. How to extend the service life of galvanized steel gratings.

1). The hot dip galvanized steel grating should be keep in good repair over its lifetime.

2). The welds should be painted with rust- resistant paint.

3). The steel grating should be kept clean, and the corrosives should be cleared in time.